Carbon Impact of Insulation: Putting Cellulose to the Test

As the building industry moves toward a greener future, the search for sustainable building materials has led many industry professionals to make the switch from conventional insulation materials to materials with lower embodied carbon. In fact, the embodied carbon of building assemblies has become more pressing than ever at the local, state and federal levels. For example, the Inflation Reduction Act of 2022 allocates billions of dollars for the development of low-carbon standards and procurement policies for the United States government. Cellulose has gained ground for its ability to reduce a home’s carbon footprint, with many developers turning to cellulose to tackle embodied carbon, dial up comfort and improve the longevity and durability of their builds.

In a recent carbon-impact for comparison study conducted by Builders for Climate Action, an organization that evaluates the impact of buildings on our climate, cellulose insulation was found to provide the lowest carbon footprint and the highest amount of net carbon storage out of a range of common insulation products. Here’s how:

Carbon Impact Comparison: Laying the Groundwork

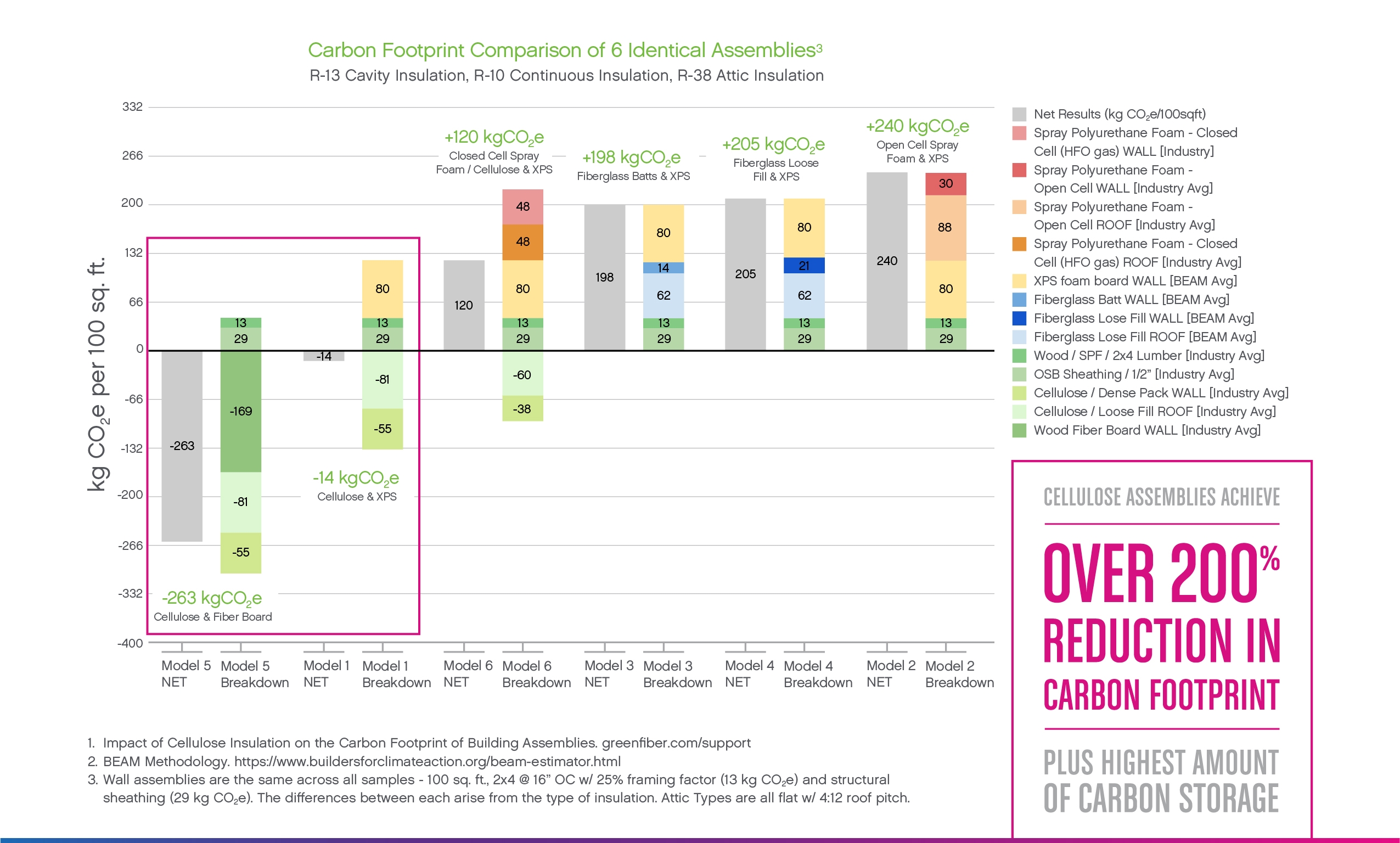

The research team evaluated six identical home-building assemblies, including wall framing, structure and insulation, and roof insulation, using 100 square feet of coverage area and an R-value of 10 as the performance criteria. Each assembly was based on typical wood-frame construction, with the carbon footprint for the framing (13 kilograms CO2e) and structural sheathing (29 kilograms CO2e) consistent across samples.

To validate claims regarding the sustainability value of cellulose insulation, the study analyzed:

- Global Warming Potential

- Carbon footprints for insulation, framing and sheathing

- The percentage reduction in carbon footprint from the assembly with the highest example

The team used Building Emissions Accounting for Materials, or BEAM, a carbon estimator tool that calculates total emissions for different product types and assemblies to generate comparisons for cellulose and competitor materials. The differences between each sample arose entirely from the type of insulation specified.

Embodied Carbon Value of Cellulose vs. Alternative Insulations

1. GWP: Cellulose has the lowest embodied carbon of all insulation types prior to the inclusion of carbon storage value. With carbon storage attributed, this type of insulation provides the highest degree of net carbon storage in the study.

2. Carbon footprints of standard wall and roofing assemblies (including wall framing, structure and insulation and roof insulation): For comparison, each assembly is represented with two different bars in the chart. The gray bars represent the net carbon footprint results (carbon emissions minus carbon storage), and the colored bars represent the contribution of each material in the assembly to the net total. Colored areas below the zero line represent carbon storage, and those above the zero line represent emissions.

(Click here to view larger image)

3. Percentage reduction in carbon footprint: In the study, cellulose in cavities with wood-fiberboard continuous wall insulation is shown to achieve 210% carbon footprint reduction, outperforming open-cell spray foam and fiberglass batts. The results demonstrate that insulation choices can have a dramatic impact on the carbon footprint of an entire assembly, and therefore an entire house.

Sustainable Insulation: How Cellulose Reduces Carbon Emissions

Cellulose insulation is made of up to 85% post-consumer paper material, reducing greenhouse gas emissions and providing the eco-friendly benefits critical for a sustainable building assembly. Because of these benefits, cellulose offers an easy-application alternative to comparable insulation materials. SANCTUARY® by Greenfiber is the only major insulation material that reduces global warming potential because it’s made from living trees that lock in carbon for the life of the product, helping building teams achieve net-zero builds, reduce global warming and offset carbon emissions.

- If builders specify SANCTUARY in new homes1 and homeowners install it in their attics or walls, 12.4 million tons of carbon dioxide could be removed from the atmosphere.

- A SANCTUARY Home locks up 1.34 tons of carbon2, which is equal to planting 3,600 trees.3

- By choosing a carbon-negative product today, you’ll lower the carbon footprint of your assembly for its lifetime.

Want to know more about the carbon impact of different insulation products on the market? Check out the full study.

[1] Carbon capture goal is based on insulating all underinsulated attics in the U.S. with 65 bags of SANCTUARY (32,875 homes built before 1965) and installing SANCTUARY in the attics at R-38 and exterior walls at R-13 of new home builds in 2022 (13,107,000 new home starts).

[2] Based on installing 235 bags of SANCTUARY in the attic and walls of home. Based on the CIMA/CIMAC LCA for manufacturing and the WWF Biogenic Carbon Footprint Calculator for Harvested Wood Products. Tree sequestration statistics are based on the EPA Greenhouse Gas Equivalencies Calculator, https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator.

[3] Greenhouse Gas Equivalencies Calculator (1.5 acres; based on planting trees 5 feet apart, equaling 2,400 trees per acre).

- Category: Projects